-

Phone

-

(+91)-9810078278

nutechscaff@gmail.com

-

Address

-

K - 576. NAWADA INDUSTRIAL AREA, UTTAM

NAGAR, NEW DELHI - 110059. WITH GOOGLE MAP.

Welcome To Nu Tech Scaffolding

(+91)-9810078278

nutechscaff@gmail.com

K - 576. NAWADA INDUSTRIAL AREA, UTTAM

NAGAR, NEW DELHI - 110059. WITH GOOGLE MAP.

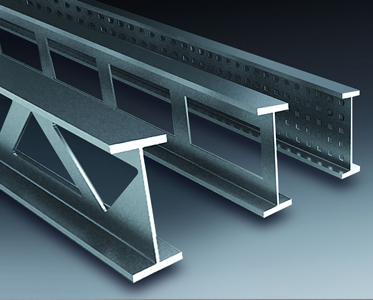

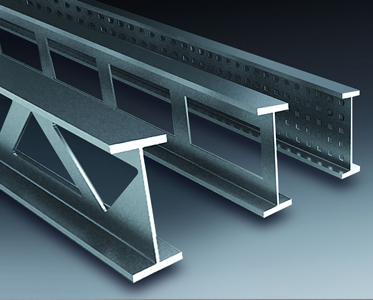

The lightweight steel fabrication includesa 100mm wide top flange which eliminates the necessity for a plywood infill, so cutting down maintenance costs. Heavy duty pressings are fitted to the beam ends ensuring adequate protection against site abuse. These incorporate a tongue location for the drophead.

Panel retaining lugs have a tapered wedge action for quick positive location of panels, ensuring tight joints and minimum grout loss. When beams are in the horizontal position they cannot be accidentally dislodged.

Engineered to support normal access loads and stop-end forms; a safety device is incorporated locking the beam to the drophead so that they cannot be dislodged when striking. Provision is made for a guard-rail post to be attached using standard scaffold tube and fittings, thus eliminating the need for an external scaffold- a big saving in construction cost.

The quick action drophead supplied complete with nuts and bolts is designed to fit on standard props or adaptors for Cuplocks scaffolding. They allowpanels and beams to be struck and re-used after only 3n or 4 days, leaving the support in position for the remaindar of the curing period of the concrete slab.

The primary head remains in contact with the concrete whilst the secondary head and its supporting wedge are realeased by a single hammer blow. The height of the drophead is 214mm and the striking distance allows the beams and panels to drop only 115mm for hte their safe removal a marked improvement in terms of speed and safety compared with other systems.

The drophead has a load carrying capacity of 40kN.

Special care has been taken to ensure that beams cannot be accidentally dslodged once located with the drophead primed.